CASE STUDY: Casamar

Crafting Identity Through Form

Positioned along 283 linear feet of prime oceanfront in Pompano Beach, Casamar is a 22-story luxury condominium developed by Related Group. The tower brings together visionary architecture by Arquitectonica and interiors by the award-winning Rockwell Group, to create a refined residential experience. With 119 private residences featuring floor-to-ceiling glass, private elevators, and expansive terraces, the building is thoughtfully designed to capture panoramic views of the Atlantic Ocean.

Casamar’s interiors take cues from its coastal setting, with sweeping curves and sculptural forms shaping the flow of its amenity spaces. These include sunrise and sunset pools, a Promenade Lounge with unobstructed ocean views, a modern fitness center, and curated art installations throughout. The result is an environment where sophisticated design and natural beauty converge to set a new standard for oceanfront living in South Florida.

Precision Fabrication Brings Architectural Vision to Life

McKenzie Craft was engaged to engineer, fabricate, and install more than 10,000 square feet of custom architectural millwork and structural steel throughout Casamar’s lobby and adjacent amenity spaces. Our scope included custom millwork, natural marble, and glass throughout the amenity levels that aligned with the project’s refined design while ensuring long-term durability and functionality.

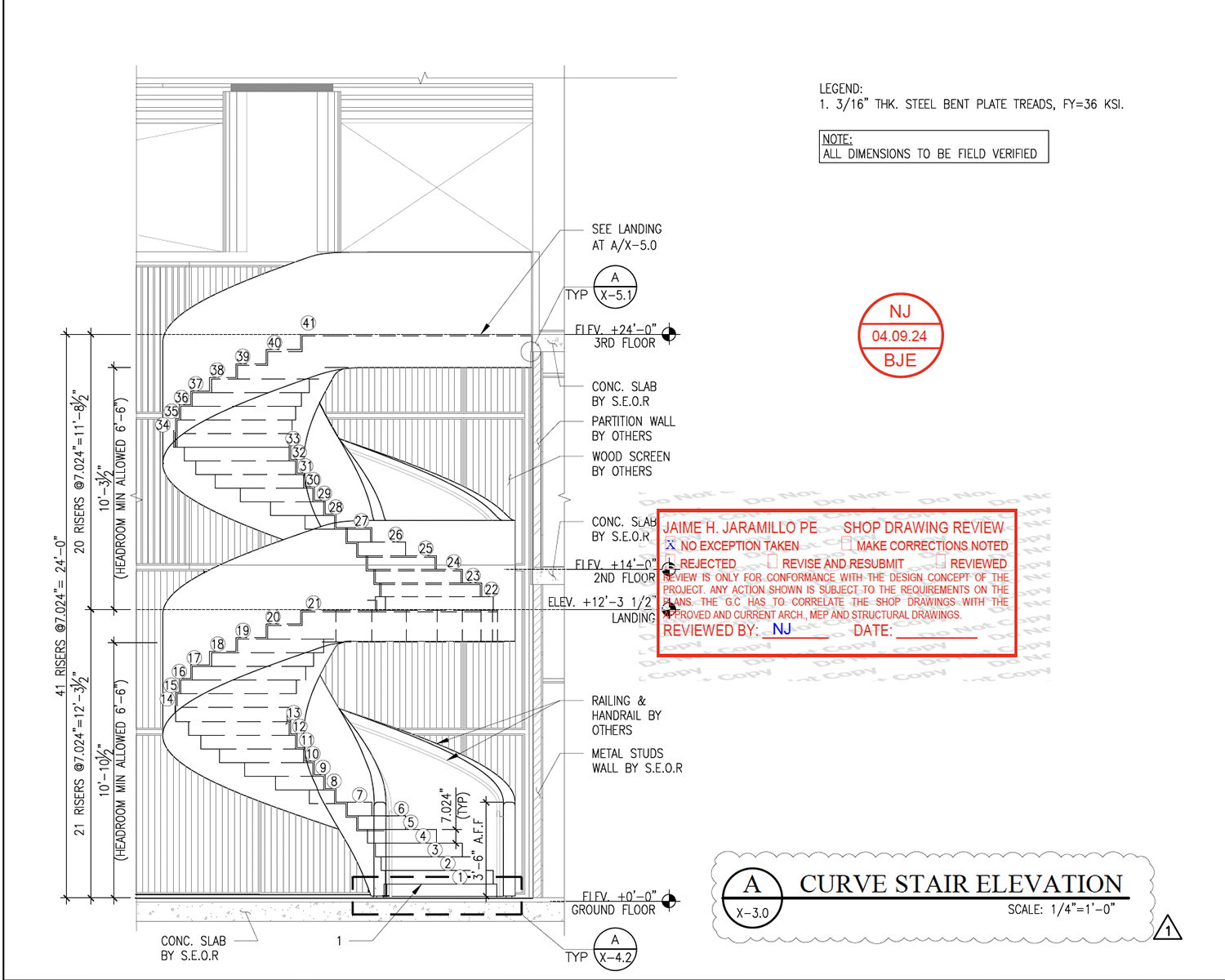

At the center of our work was the staircase connecting the first and third floors: a six-ton steel-core spiral that anchors the building’s ocean-facing atrium. Clad in white oak paneling with sculpted solid white oak handrails and finished with terrazzo treads, Venetian plaster, and integrated LED lighting, the staircase required an extraordinary level of engineering and coordination. Its sculptural presence not only defines the space visually but also demonstrates the technical precision involved in achieving the architect’s vision.

Complementing this focal point, we fabricated and installed a range of other detailed elements: floor-to-ceiling curved screen walls, divider walls with full-height pivot doors featuring fluted glass and oak slats in fitness and lounge areas, decorative column wraps, back-of-house cabinetry, and casework throughout. White oak was selected as the primary material for its warmth, uniform grain, and ability to deliver visual consistency across large-scale surfaces.

McKenzie Craft played a key technical role early in the project, developing detailed shop drawings and 3D models that supported both fabrication planning and installation sequencing. We also assumed responsibility for the staircase’s structural steel fabrication, allowing tighter integration between steel and millwork. Final installation was completed by our in-house field team, ensuring alignment between design intent and execution down to the last detail.

Meeting Complex Design Goals Through Innovation and Collaboration

Casamar’s millwork scope presented a range of technical and logistical challenges. With this expansive suite of custom fabrications distributed across multiple active construction zones, the project required disciplined coordination to manage site access, delivery schedules, and seamless integration with other trades.

The interior design embraced a minimalist, detail-driven aesthetic. Flush surfaces, concealed joints, and seamless transitions were used throughout to evoke a sense of calm and refinement. Achieving this visual clarity across expansive surfaces demanded extreme precision in fabrication and installation. The selection of oak veneer allowed for uninterrupted visual flow and material unity across full-height panels, expansive built-ins, and custom dividers.

Among the most intricate elements were the oak slat walls and pivot doors, which incorporated integrated fluted glass, LED reveals, and concealed hardware. To achieve the desired scale and performance, the team fabricated the pivot doors from ¼" aluminum tubing—selected for its strength and rigidity—then wrapped them in veneer to align with the design aesthetic. This solution, which would not have been possible with wood alone, allowed the original design intent to be realized without compromise. These assemblies required advanced CAD modeling and CNC programming to maintain tight tolerances while accommodating concealed lighting and mechanical systems. Grain-matched veneer panels were sequenced and fabricated with meticulous attention to continuity and alignment, ensuring a flawless finish across compound geometries.

The sculptural staircase was the most technically demanding component. Engineering a six-ton steel spine to match the helical geometry of the stairs required custom steelwork and extensive coordination with supporting trades. Oak cladding and metal trim was fabricated to follow the complex curvature, aligning with terrazzo treads and blending seamlessly into the Venetian plaster shell. Integrated lighting along reveals and railings was designed and installed with precision to preserve both function and visual elegance. Installation sequencing was critical and required exacting quality control and on-site craftsmanship to meet the project’s demanding aesthetic and structural standards.

McKenzie Craft’s early involvement allowed our team to contribute valuable insight into material selection, detailing strategies, and installation logistics. Fabrication mock-ups and prototypes were used to validate key design approaches and test material performance. Our team provided constructibility recommendations and value engineering options that preserved design integrity while improving long-term performance. Modular prefabrication techniques helped reduce installation time and mitigate risk during transport and on-site handling.

Through consistent collaboration with the architect, interior designer, general contractor, and ownership team, we maintained clear communication and resolved challenges in real time. This collaborative, proactive approach enabled us to meet aggressive schedule targets and deliver a finished product that exceeded expectations.

From Design Inception to Flawless Installation

Spanning approximately 24 months from initial design to final installation, the project benefited from McKenzie Craft’s involvement at every key phase. Early technical input helped shape millwork strategies that aligned with the overall design intent while ensuring feasibility and efficiency in production.

Our fabrication process relied heavily on 3D modeling, parametric design software, and CNC technology to deliver the precision required for Casamar’s clean lines and curved forms. Full-scale mock-ups were developed to resolve complex junctions and confirm finishes in advance of full production. Larger assemblies were prefabricated and dry-fitted off-site, allowing for better control and minimizing potential issues during installation.

Installation was led by McKenzie Craft’s experienced field team, who coordinated closely with other trades to ensure a clean and efficient workflow within the active job site. Dimensional accuracy, grain matching, and lighting integration were monitored throughout. Final field adjustments were made with a high level of care to preserve the quality and consistency achieved during fabrication.

Innovation, Collaboration, and Craftsmanship Elevate Oceanfront Living

Casamar stands as a benchmark for high-end residential fabrication, showcasing McKenzie Craft’s ability to execute complex architectural features with clarity and precision. Our team’s dual role in structural engineering and millwork fabrication for the spiral staircase exemplifies the added value we bring through integrated technical capabilities.

The project also highlights the importance of early collaboration and design-assist partnerships in achieving challenging design goals. By working alongside the architect, interior designer, and contractor from the outset, we were able to deliver a cohesive environment that marries architectural intent with constructible, enduring craftsmanship.

Casamar affirms McKenzie Craft’s position as a leader in custom fabrication for luxury residential and hospitality environments. Our focus on thoughtful engineering, artisanal detail, and adaptive collaboration continues to drive the success of our most ambitious work.